Internal combustion engines convert the chemical energy in hydrocarbon fuels into mechanical power through the compression and combustion of air and fuel inside the engine’s cylinders.

Combustion releases the fuel’s energy, moving pistons that produce mechanical power. Each upward or downward movement of the piston is called a stroke. The most common types of internal combustion engines are the two-stroke (aka two-cycle or 2T) and the four-stroke (aka four-cycle or 4T).

Two-Stroke and Four-Stroke Differences

The fundamental difference between two-stroke and four-stroke engines is in their gas-exchange process, or more simply, the removal of the burned gases at the end of each expansion process and the introduction of a fresh fuel-air mixture for the next cycle.

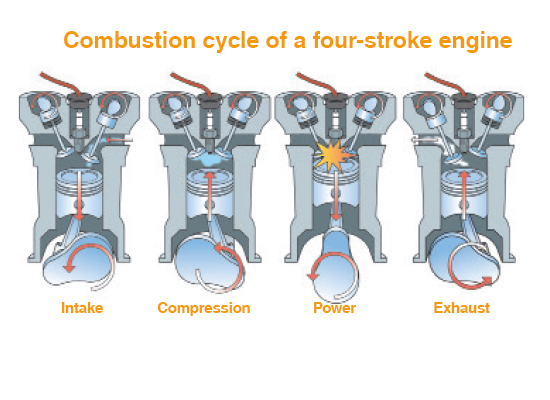

Four-stroke engines require four stages to convert fuel into mechanical energy, which takes two full rotations of the crankshaft. Intake and power happen on alternating downward strokes and compression and exhaust happen on alternating upward strokes:

Intake Downstroke:

- The piston moves down, creating a vacuum.

- The intake valve opens, drawing a mixture of air and fuel into the cylinder.

Compression Upstroke:

- The intake valve closes.

- The piston moves up, compressing the fuel-air mixture and increasing its pressure and temperature.

Power Downstroke (Ignition):

- When the piston reaches the top of the cylinder, the spark plug ignites the compressed fuel-air mixture.

- The explosion forces the piston forcefully downward, generating power.

Exhaust Upstroke:

- The exhaust valve opens.

- The piston moves up, pushing the spent exhaust gases out of the cylinder.

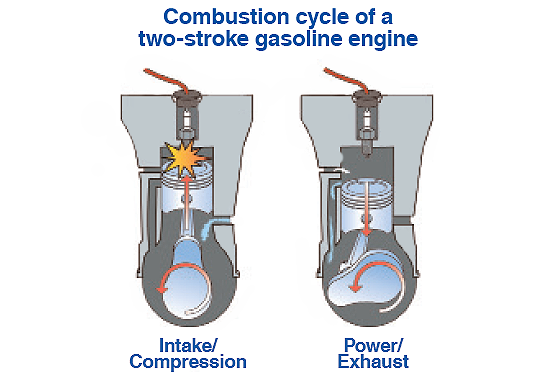

Two-stroke engines complete the same four-step power cycle (intake, compression, power, exhaust) in two piston strokes and one crankshaft revolution. Since a two-stroke engine produces power in a single crankshaft rotation it makes power twice as often as a four-stroke engine.

The piston covers and uncovers the intake, exhaust and transfer ports to move fuel/oil/air in and exhaust out of the combustion chamber. Compression and intake are combined on each upstroke, power and exhaust on each downstroke:

Intake and Compression Upstroke

- Above the piston the fuel/oil/air mixture is compressed in the combustion chamber.

- Below the piston a vacuum draws fresh fuel/oil/air into the crankcase through an intake port.

Power and Exhaust Downstroke

- Above the piston the spark plug ignites the compressed fuel/oil/air mixture forcing the piston down and the exhaust port is uncovered allowing burned gases to escape

- Below the piston the transfer port opens, forcing the fresh fuel-air/oil mixture from the crankcase into the combustion chamber and pushing the exhaust gases out (scavenging).

Applications

Two-stroke engines typically use fewer parts and are less expensive to build than four-stroke engines. They are also lighter and capable of higher power-to-weight ratios. However, two-stroke engines generally wear more quickly than four-stroke engines because engine components are not lubricated with a dedicated oil. Choosing a high-quality two-stroke oil can significantly reduce engine wear. Two-stroke engines are ideal in lightweight applications like chainsaws, weed trimmers, outboard motors, dirt bikes, snowmobiles, racing vehicles and other off-road applications.

Four-stroke engines typically produce more torque at lower rpms, better fuel efficiency and lower emissions. They are also more durable due to dedicated lubrication. They are common in heavier, extended-use and on-road vehicles like motorcycles, UTVs, cars and trucks.

Four-Stroke Lubrication

Four-stroke engines are lubricated by oil held in an oil sump. The oil is distributed through the engine by splash lubrication or a pressurized lubrication pump system; these systems may be used alone or together. The oil is not mixed with the fuel or burned in the combustion cycle.

- Splash lubrication is achieved by partly submerging the crankshaft in the oil sump. The momentum of the rotating crankshaft splashes oil to other engine components such as the cam lobes, wrist pins and cylinder walls.

- Pressurized lubrication uses an oil pump to provide a pressurized film of lubricant between moving parts such as the main bearings, rod bearings and cam bearings. It also pumps oil to the engine’s valve guides and rocker arms.

Two-Stroke Lubrication

Two-stroke engines employ a total-loss lubrication system that combine fuel and oil before it reaches the engine’s moving components. The fuel/oil mixture provides lubrication for the crankshaft, connecting rods, piston rings and cylinder walls. The oil is burned with the fuel in the combustion cycle.

- Oil-injected two-stroke engines inject the oil directly into the engine, where it mixes with the fuel.

- Pre-mix two-stroke engines require combining the fuel-oil mixture before installation in the fuel tank.

AMSOIL provides a full line of premium synthetic two-stroke and four-stroke oils to protect whatever engine you are using. AMSOIL 2-stroke oils are specifically engineered to address the limitations of conventional 2-stroke oils and provide superior engine lubrication. Benefits of AMSOIL 2-stroke oils include:

- Outstanding performance in pre-mix and injected engines.

- Prevents piston ring and exhaust power valve sticking.

- Exceptional cold-temperature fluidity.

- Superior protection against wear.

- Low smoke and odor.

by David Hilgendorf

AMSOIL Technical Writer and 20-year veteran of the motorcycle industry. Enjoys tearing things apart to figure out how they work. If it can’t be repaired, it’s not worth owning.