I think most people have an idea of what lubrication is and that it is required to keep moving parts moving and prevent them from coming into contact with one another. In other words, we want the lubricant to minimize the effects of friction and protect moving parts.

Friction is both a positive and negative force in our daily lives. It is essential for everyday tasks such as walking, where friction gives you the ability to create traction between yourself and the ground. It is also the principle behind the braking systems found in automobiles. Friction can also be our enemy. The heat generated as a result of friction can cause damage.

An oil’s primary function is reducing friction. It does this by creating a film between surfaces to prevent contact, thereby reducing friction. However, lubricants are frequently needed to do more than just provide a slippery film between moving surfaces in contact. They are tasked to carry out several other functions, some of which might not immediately spring to mind when you think about engine oils or other lubricants. Let’s take a closer look at six not-so-obvious lubricant functions.

Transfer Energy

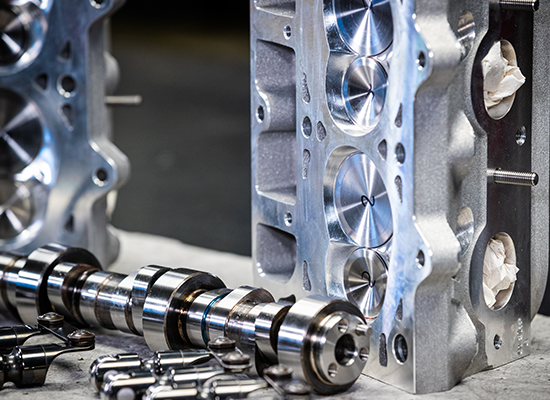

Because muid lubricants are not readily compressible, they can act as an energy-transfer medium, such as in hydraulic equipment or valve lifters in an automotive engine. This key property allows lubricants to be used in heavy equipment to transfer energy from a hydraulic motor to pistons, which provide the means to actuate shovels, forklifts and so on. Automatic transmissions are another good example; the fluid inside the torque converter creates and transfers energy to make the transmission work.

Clean

Lubricants maintain internal cleanliness by suspending contaminants within the fluid or by preventing the contaminants from adhering to components. Base oils possess a varying degree of solvency that assists in maintaining internal cleanliness. Solvency is the ability of a fluid to dissolve a solid, liquid or gas. While the solvency of the oil is important for maintaining cleanliness, detergents and dispersants play a key role. Detergents are additives that prevent contaminants from adhering to components, especially hot components such as pistons or piston rings. Dispersants are additives that keep contaminants suspended in the fluid. Dispersants act as a solvent, helping the oil maintain cleanliness and prevent sludge formation.

Cool

Lubricants are used to cool the parts of a component or machine while in operation – like a fan or air conditioner is used to cool the inside of a house. Reducing friction minimizes heat in moving parts, which lowers the overall operating temperature of the equipment. Lubricants also absorb heat from contact surface areas and transport it to a location to be safely dispersed, such as the oil sump. Heat transfer ability tends to be a trait of the base oil’s thickness – lighter oils tend to transfer heat more readily.

Seal-Out Contaminants

Lubricants are used to seal components from outside contamination, like windows in a house or automobile. They can act as a dynamic seal in locations such as piston rings and cylinder contact areas to prevent contamination.

Dampen Shock

A lubricant can cushion the blow of mechanical shock, just as a shock absorber in a car dampens road vibrations and imperfections. A highly functional lubricant film can resist rupture and absorb and disperse these energy spikes over a broad contact area. When the mechanical shock to components is dampened, wear and damaging forces are minimized, extending the component’s overall life.

Protect Against Corrosion

A lubricant must have the ability to prevent or minimize internal component corrosion. Lubricants accomplish this either by chemically neutralizing corrosive products or by establishing a barrier between the components and the corrosive material.

Superior Protection & Performance

The important takeaway here is that lubricant quality is not about excelling in one performance area; rather, it’s about the entire set of performance properties. This is another reason why AMSOIL synthetic lubricants provide such excellent value. In the key areas of quality, reliability and service life, AMSOIL synthetics are second to none. They not only excel in reducing friction, they provide across-the-board performance and protection in all crucial aspects of lubrication.

by Alex Thompson

AMSOIL Market Manager and product expert.