Brake fluid can and does go bad. Despite being one of the most crucial components for safety and performance, changing brake fluid is one of the most neglected maintenance tasks.

In fact, people rarely change their brake fluid before it goes bad. They often wait until they hear the grinding sound from the wear indicator on the brakes, then change the brake pads and bleed the brakes in the process. But the truth is, regularly maintaining your brake fluid is essential to ensure firm, reliable braking.

Why Brake Fluid Goes Bad

Brake fluid is hygroscopic, meaning it likes water just like a sponge. Brake fluid absorbs moisture from the air over time through the seals, hoses and even the brake reservoir when it’s opened. This absorbed water lowers the fluid’s boiling point, which can lead to dangerous brake fade and a spongy pedal feel.

Dry vs. Wet Boiling Points

When brake fluid reaches its boiling point during operation, vapor forms in the brake lines, making it compressible. This produces a soft or spongy brake pedal that can undermine brake performance. If you frequently carve scenic mountain roads or rip through corners, the last thing you want is compromised stopping power.

Since brake fluid is hygroscopic, required industry testing simulates real-world field conditions. The wet and dry boiling points are tested to help illuminate the quality of a brake fluid.

Here is a quick description of boiling points:

Dry equilibrium reflux boiling point (ERBP): Measures the boiling point of the fresh fluid right out of the bottle before it has been contaminated by moisture.

Wet equilibrium reflux boiling point (WERBP): Measures the boiling point of fluid after it has had time to absorb moisture from its surroundings, including conditions under which the average vehicle operates (3.7% water contamination, to be exact).

Effects of Moisture Contamination

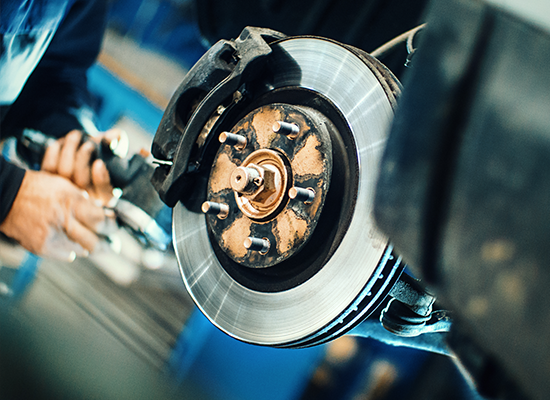

While brake fade caused by boiling fluid is an immediate concern, moisture contamination also has long-term consequences. Water in the brake system accelerates the corrosion of metal components like calipers, master cylinders and ABS control valves. Over time, this can lead to rust, leaks and expensive repairs.

AMSOIL DOT 3 & 4 Synthetic Brake Fluid

The unique chemistry behind AMSOIL synthetic brake fluids increases boiling points well beyond DOT standards, even when contaminated with 3.7% water. AMSOIL brake fluids maintain a stable viscosity over a wide temperature range and flow easily at the high pressures generated in today’s automotive brake systems to deliver solid, reliable braking. A nitrogen blanket is added to each bottle during manufacturing to purge moisture and ensure the maximum level of performance.

AMSOIL DOT 3 & 4 Synthetic Brake Fluid is overbuilt for extra safety and performance. With a wet boiling point of 368°F (187°C), it far exceeds the minimum requirements of 284°F (140°C) for DOT 3 fluid and 311°F (155°C) for

DOT 4 fluid.

In addition, its low-viscosity formula ensures excellent responsiveness in modern ABS and traction-control systems. AMSOIL DOT 3 & 4 Synthetic Brake Fluid maintains low compressibility under severe heat, delivering a steady and firm pedal feel. It protects calipers, lines and seals, helping extend the life of key brake system components.

AMSOIL DOMINATOR® DOT 4 Synthetic Racing Brake Fluid

AMSOIL DOMINATOR DOT 4 Synthetic Racing Brake Fluid provides racers with a brake fluid that delivers superior high-temperature performance, preventing brake fade and vapor lock. High boiling points of 580°F/304°C (dry) and 399°F/204°C (wet) minimize vapor formation. A nitrogen-blanketed design avoids moisture absorption during manufacturing and storage.

Operating conditions – and, thus, fluid life – vary depending on the environment, equipment type and application. As a rule of thumb, change your brake fluid every two years for maximum performance. However, if you’re driving involves spirited sessions or long descents, replacing your brake fluid annually is recommended to maintain peak performance. For racing applications, change AMSOIL DOMINATOR DOT 4 Synthetic Racing Brake Fluid once a year for maximum performance.

Don’t Push it Off

While changing brake fluid can feel like a chore you can delay, ignoring it invites moisture buildup, corrosion of key components and poor braking performance. Brake fluid is more than just another maintenance item; it’s your front line of defense for vehicle safety and performance. But with the right fluid and regular maintenance, your vehicle’s brake performance can remain as sharp as ever.

by Alex Thompson

AMSOIL Market Manager and product expert.

Share: